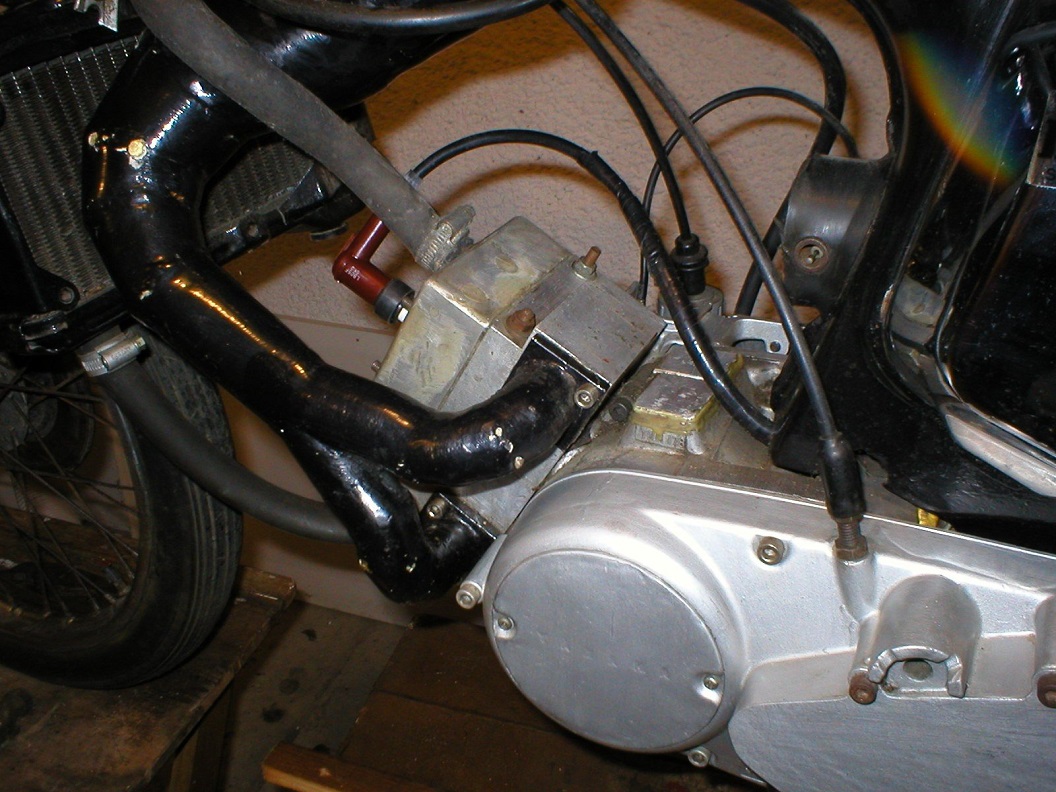

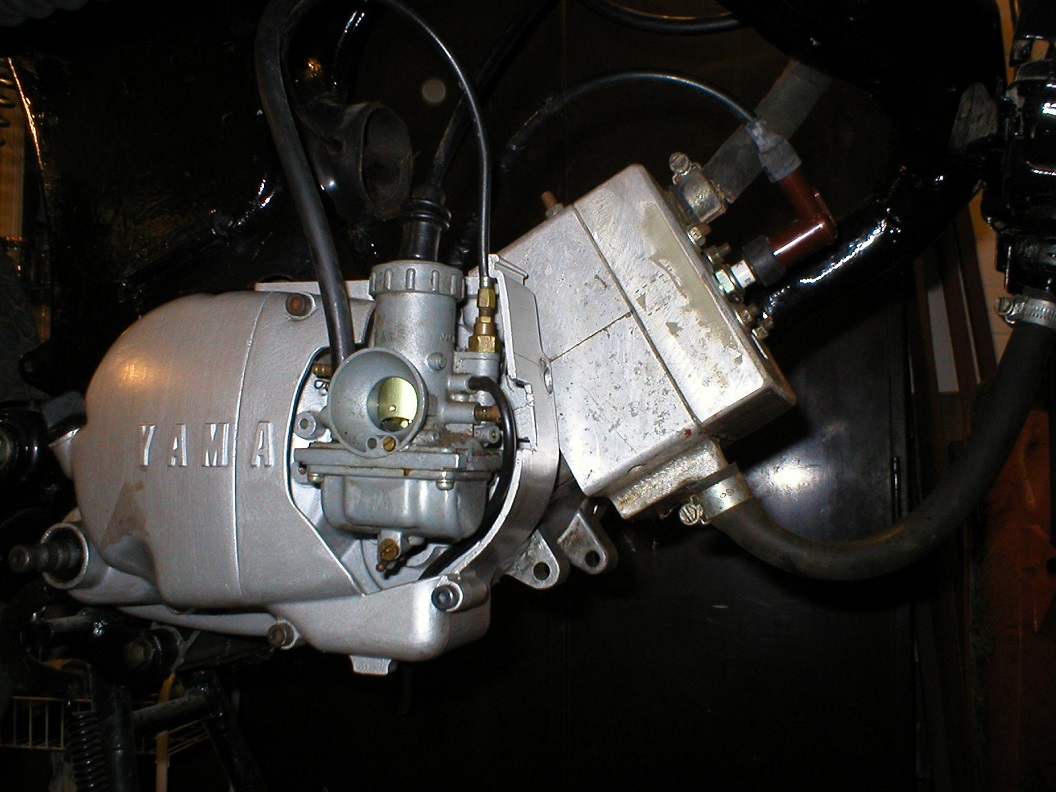

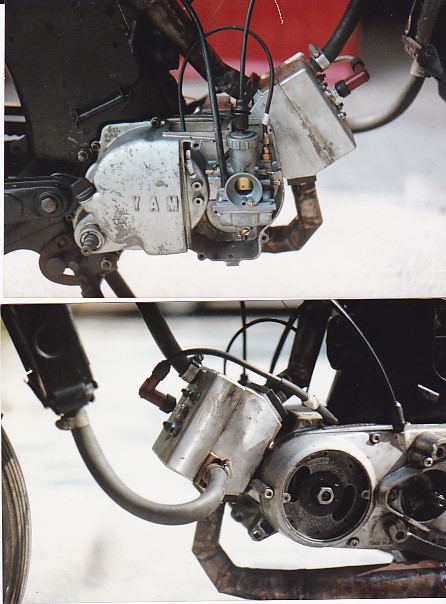

The YAMAHA FS1E Twin exhaust port water cooled project

|

|||||||||||||||||||||||||||

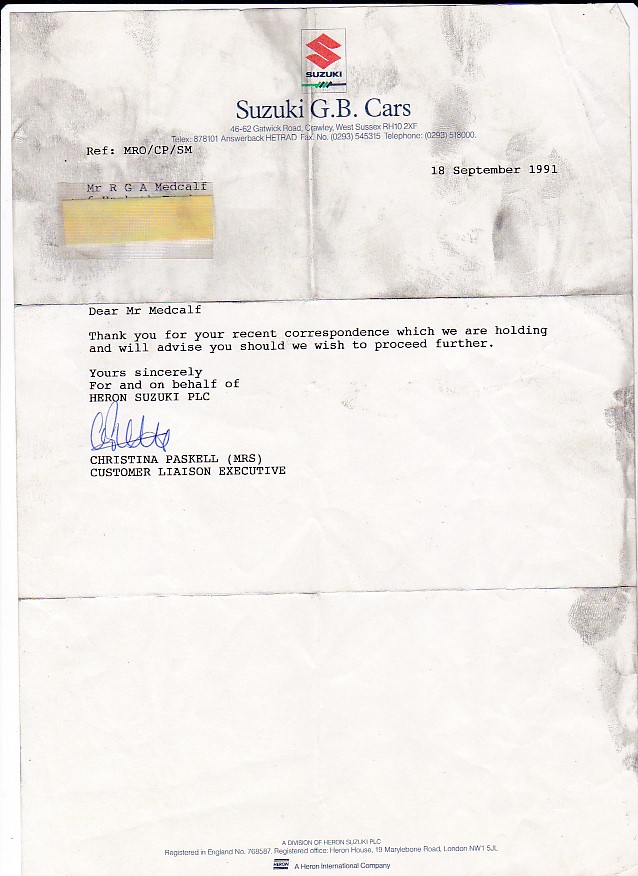

| - The first letters from Suzuki was read with great excitement. Hence being covered in my greasy dabs. |

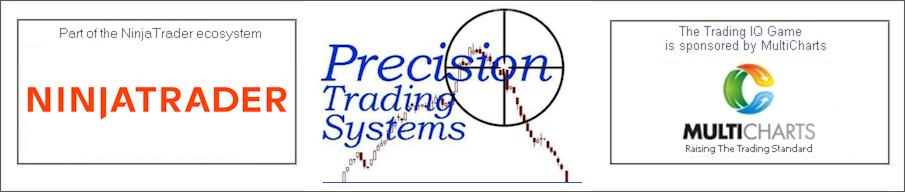

The letter from Yamaha was a bit mysterious and they sent everything back to me. They did not mention any objection to me butchering one of their beloved Fizzys though. |

|

Letter from Rotax stating they already tried this idea. Rotax together with Morbidelli are widely regarded as being the Worlds best racing two stroke engine makers so I was at least happy to know that great minds were thinking alike. These things just have to be tried out don't they? |

|

| A nice letter from Honda |

|

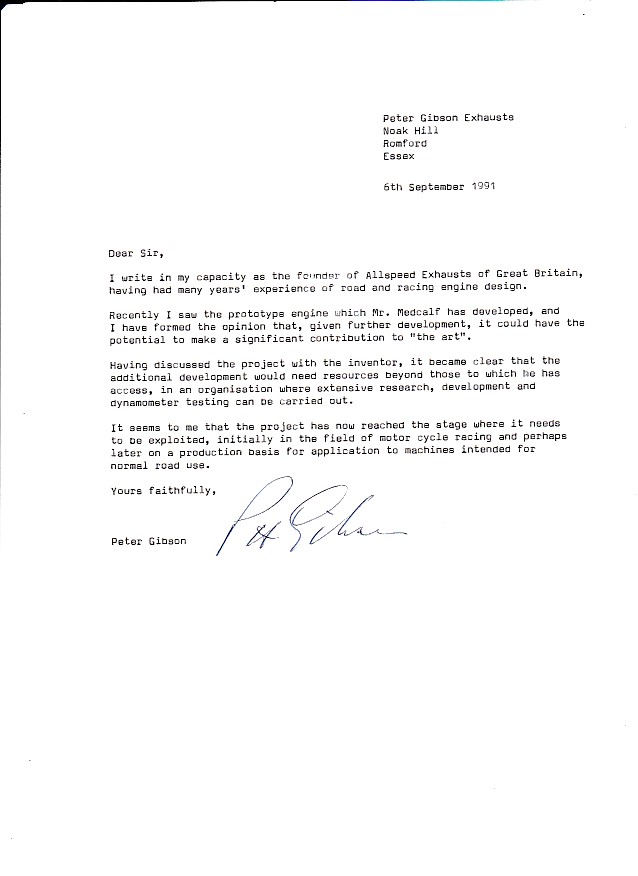

Letter from Peter Gibson of Allspeed exhausts I learned a few things from Peter as he was one of the best exhaust makers in the UK and a very helpful man with a one man operation. 1. On expansion chamber design, if the tail pipe exit is connected at the end of the cone this is a high pressure area and thus will make more noise than is ideal. If you push the stinger pipe down inside to a low pressure area ( where the end cone meets the straight section ) you have a much quieter sound. If you ever heard the lovely tinny sound than a Yamaha IT 175 or a Honda CR 250 or even an RD 250LC kitted with Allspeeds then that is what you get if you push the stinger pipes deeper inside the last cone. I also note that if this happens to make the stinger longer than is needed and thus more restrictive then its diameter must be widened to prevent over heating due to a rise in back pressure. 2. When the noise level laws got changed the regular Micron and Allspeed pipes were above the limit so Peter had to work out how to reduce the noise, surprisingly a large part of the noise was emitted from the exterior surface of the pipe itself instead of just the tail pipe. The solution is showed me was they used a double skin in the sense of two layers of 1mm thick tubing. Also it surprised me to learn that the double skinned expansion chamber made less power than the single skin version. I later learned from Ed Seykota on his radial momentum page that it can be observed with a strobe light that the chamber actually swells and shrinks over the course of the suck, squeeze, bang blow cycle that engines make. So it seems certain that a rigid pipe which cannot expand and contract does not work as well as one which is flexible. Rather an odd thing to realise that. Think how difficult it would be to make double skinned pipe with welds and curves. I used the internal tailpipe logic in any other expansion chambers I made and got the nice tinny crackle sound and lower decibels. Compare that to the sound of a Fizzy that sports a Micron exhaust and you will get the point. |

|

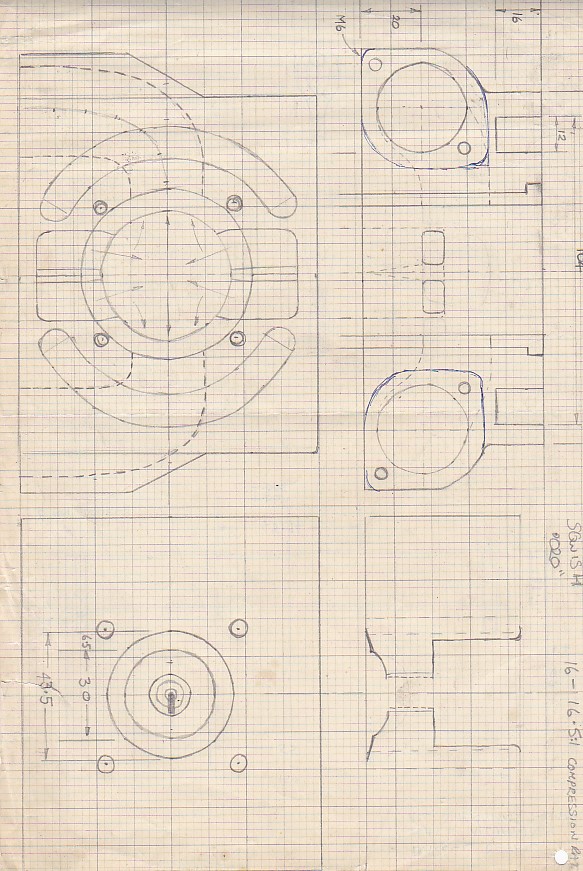

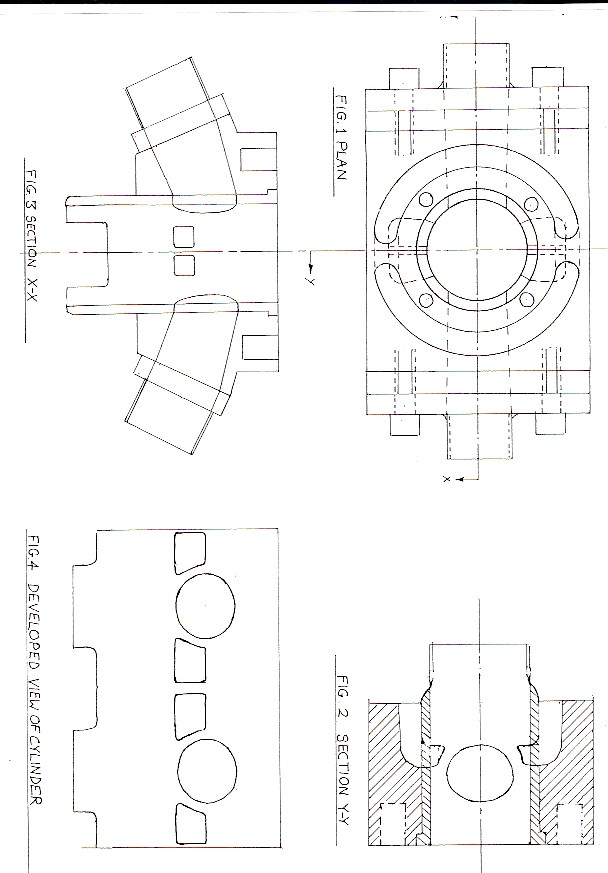

Design of the two into one expansion chamber cylinder ( less effective version ) Note the upon its first journey out of the cylinder the exhaust gases start off by being made to do a sharp 90 degree turn which must impede flow to some degree. The same head was used in both designs and both had a squish clearance of 20 thousands of an inch |

|

Drawing of the more powerful and better design with dual straight opposite exhaust ports going into separate expansion chambers |

|

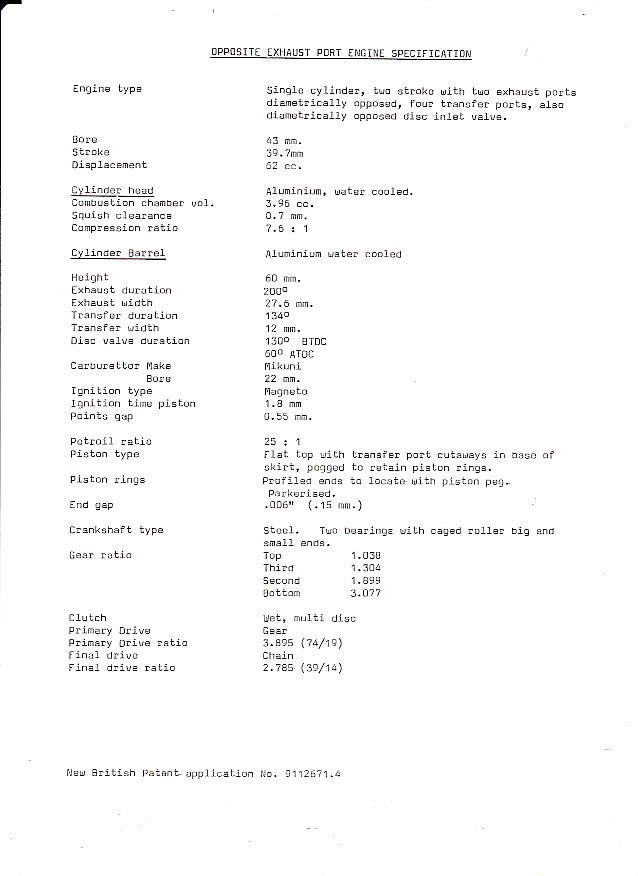

Water cooled FS1E Technical Specifications : Only a single top piston ring was used and it was re dowled so the ring ends missed the ports. |

|

| The next part of this story is related to another design I came up with, but someone else went ahead with it and I did not... |

|

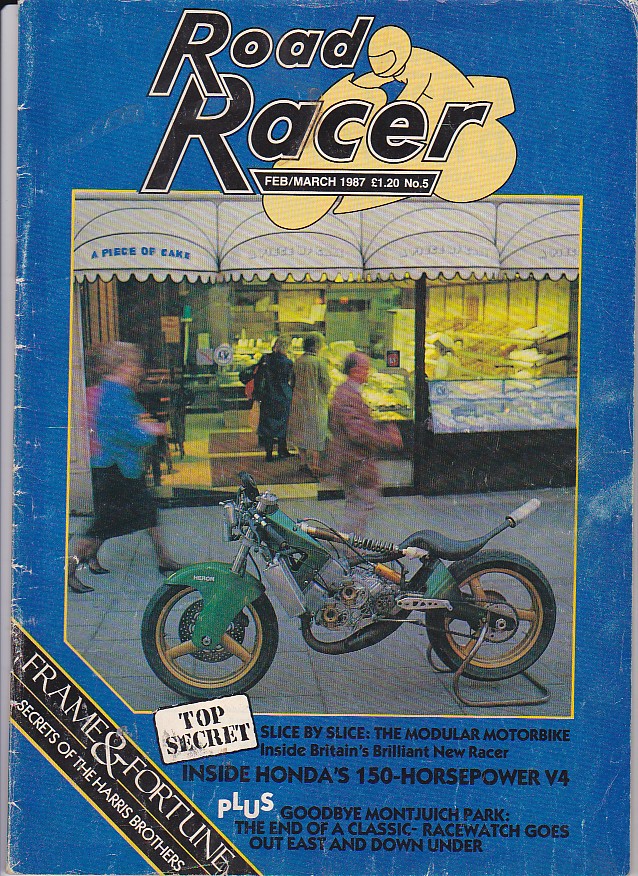

The dual disc valve per cylinder invention was more succesful in terms of ideas and it was actually made into a race engine design by Exactweld It made about 72 bhp but had a high speed misfired they could not work out. The rather clever design used the engine as part of the frame thus saving a lot of weight and cost of materials, the engine of course has to be much stronger to stand the extra loads put on it. You can read about it here in article featured in the Road Racer magazine from February - March 1987 Reading this gave me a shock to read as I had drawn the same design myself four years earlier in 1983. |

|

|

|

Admin notes

|

| Page expanded on December 19th 2023 after getting a lot of visits - New responsive page GA4 added canonical this. 5/5 html sm links added - replaces old page from 2006 |