|

The holes shown are to allow complete filling of the mould without trapping air at the highest point, which would otherwise occur as its a closed mould.

|

|

Home Market report Optimising trade size Downloads Open trades Latest trades

YAMAHA RD 250LC, RD350LC, RD400 INLET MANIFOLD

How its made...

|

The holes shown are to allow complete filling of the mould without trapping air at the highest point, which would otherwise occur as its a closed mould.

|

|

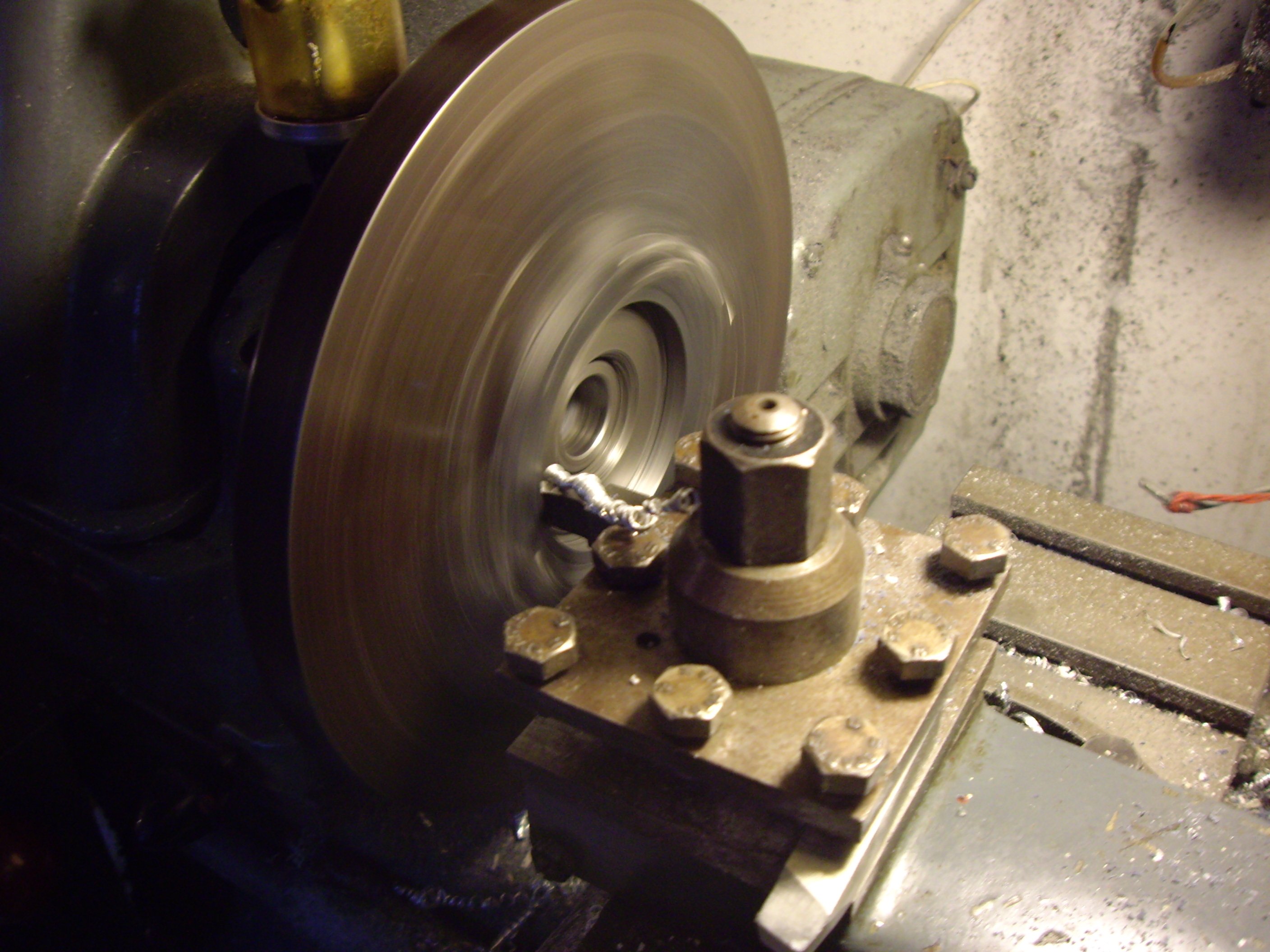

| Manufacture of the steel back plate | |

|

|

|

|

|

|

Cost per pair £90 + p&p

Discounts given for bulk or wholesale.

|

|

How its made...

The first thing to do was examine the old manifolds to decide on a viable design for a mould to replicate them. After a weeks work I had made a basic mould which was just the basic shape with no details.

The first manifold came out fine, but many of Yamaha's details had yet to be added to the mould and this part took considerable time to achieve and several more weeks work were needed to make it perfect. The details like the number stampings on the end of the manifold were probably the trickiest to fabricate.

Replicating the exact shape of the curves and radii took many hours work with hand tools and polishing with wet and dry paper going all the way down to 1200 grade as the rubber detail was so fine that the slightest mark would show up on the finished item.

Some steel flat stock was cut up into pieces and a face plate jig fitted onto my lathe to centre them was made up. I was quoted £583 each to make 100 of these steel backing plates on a CNC milling machine, but as I didn't know how many sets I would sell, I decided it was better to make up a few plates ready to be bonded to the manifolds if any orders came in.

Once all was perfect with the mould design and the backing space void, I had to purchase a high powered vacuum pump to de-gas the rubber after it was mixed. This step is very important to gain the maximum strength and hardness of the rubber.

All in all about 1 months work was required.

Roger Medcalf

Contact by Email mailto:precisionts@gmail.com

|

Back Site map Water cooled FS1E Project